Installed a Real Locker Now My Rear Tires Show a Funny Wear Pattern

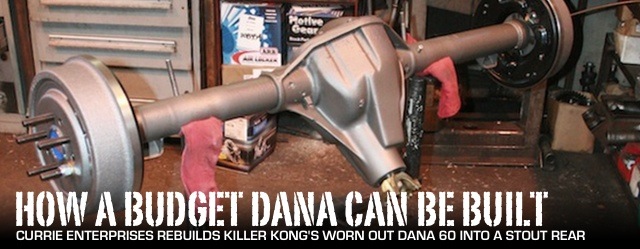

When we first proposed building a HEMI-powered '69 Dodge Charger in the same budget-minded, do-it-yourself style as say, a '75 Nova, we were nearly laughed out of the room. Building a classic Mopar carries a certain stigma – particularly when compared to most any Chevrolet or a first generation Mustang – that parts are exceptionally rare and therefore expensive; unless of course, by "classic Mopar" you mean a worn out front-wheel-drive Omni (which we don't).

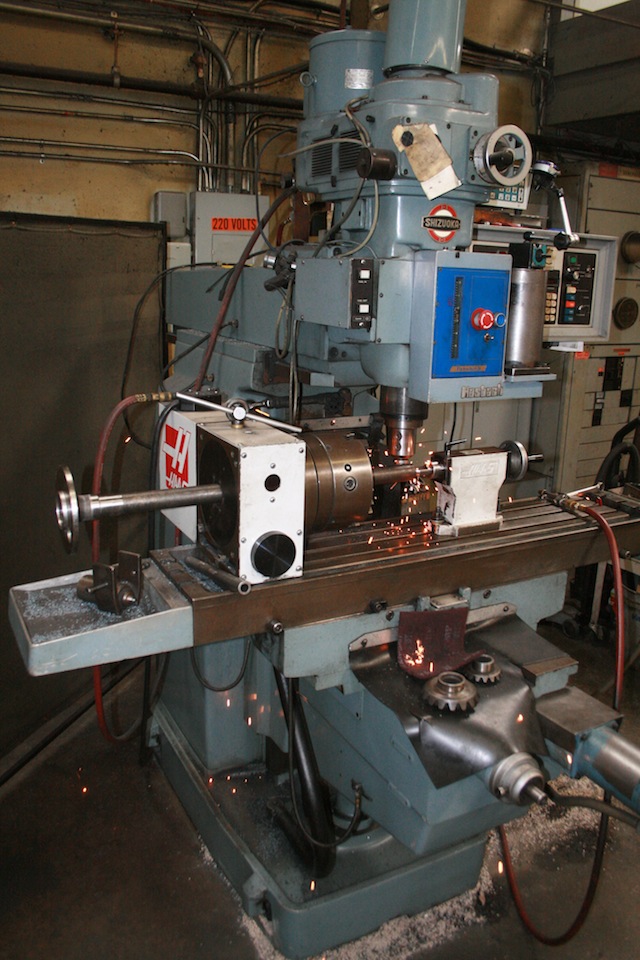

Currie Enterprises, while excelling at producing some of the strongest street, hot rod and off-road rearends, is also comprehensive fabrication and machining facility, capable of rebuilding most factory-style housings. Before any work could commence, Currie hot tanked and cleaned our old Dana housing of any remaining grease and gear oil residue.

In Killer Kong's original introduction, we mentioned that while battered and bruised, we picked up a considerably rust-free and surprisingly complete '69 Charger for $1,200. In its original form, our Dodge came factory-equipped with an open-differential (i.e. "peg leg") 8.75-inch rear.

While the 8 3/4″ served many automatic-equipped big block Super Bees, Road Runners, and even the infamous Daytona aero-cars valiantly, it was the legendary Dana 60 rear that was drafted to take the abuse delivered by the 426cui HEMI and Mopars equipped with Chrysler's A-833 four-speed.

Where to Find One Cheap

Long before the first '66 Dodge Coronet and Charger R/Ts were made available with the Dana, the Dana Corporation-built housings were first employed by heavy-duty Ford pickups in 1955, with Studebaker's 3/4 and 1-ton trucks following shortly thereafter.

Yet, it was Dodge and Plymouth who were the first and only of the Big Three to use the Dana 60 (with a ring gear diameter totaling 9.75-inches, a full inch larger than the smaller 8 3/4 and .75-inch larger than Ford's best) in passenger vehicles.

Unfortunately, finding an original Dana 60 housing from the short five-year run (1966-1971) for 'Kong proved both difficult and expensive. Since we were more concerned with having a rear that was both correct for our car (i.e. no Ford 9-inches) and stout enough to take all that we planned to throw at it, we needed to look elsewhere.

Thankfully, Dana 60 housings aren't all that exotic and can be found in nearly a quarter-century's worth of pickup trucks, SUVs, and Jeeps. We found a Ford F-350 that was getting parted out, and nabbed ours for $50. Yes, you read that right, $50 for the whole thing.

Once cleaned, Currie carefully measured our housing to match factory Chrysler specs (offset) before chucking it up on the chop saw table where the old Ford ends were cut off.

Of course, we couldn't simply bolt in our $50 Dana. Before heading over to Currie Enterprises in Anaheim, California, we cleaned up our used housing, ground off the Ford perches and brackets, and removed the worn out carrier and pinion gear. We also disassembled the kingpin knuckles which would be cut off and replaced with the proper end caps.

The big difference between our salvaged Dana 60 and the original passenger-style Chrysler housings was a four-bolt perch for a factory-supplied pinion snubber, which kept the pinion from rotating when under heavy load. Since we're planning on using a pair of Cal-Trac style traction bars, the need for a snubber was resolved.

Welcome to Currie! Let's Get Dirty

Showing up with the bare Dana 60 housing at Currie, we met with Brian Shephard who walked us through Currie's in-house capabilities, "Our full-service, one-stop shop includes a tear down and cleaning facility, full machine shop, welding shop, gear setup and assembly areas, and unit final assembly stations allowing us to service basically any need a customer may have on any of the rearend types that we service."

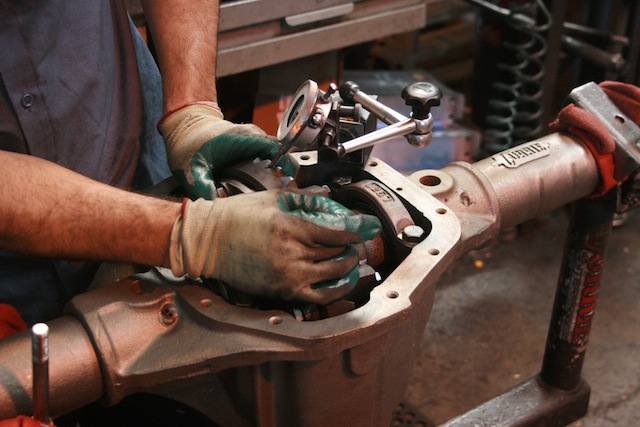

Before welding on the new billet bearing end caps, the tube ends are chamfered to accept a deeper weld, making for a more durable connection. Currie's fabricators have these unique jigs – utilizing lathe chucks – to fully rotate the housing while welding on end caps and spring perches and bracketry.

Currie's portfolio is oddly diverse, from street and strip automotive rears to mountain trail "jeeping" housings, to high-speed baja racing setups, all the way to mining and military applications. Surprisingly, conventional automotive rear ends only account for only about 40-percent of Currie's business. Shephard continued, "After 52 years in business you could say we have rearends down to a science and they're made in the USA! From building 100% new units to rebuilding as we did here, the customer gets a premium job done with premium parts and components every time – that's the only way we work."

Concerns whether welded end caps can hold up to high horsepower applications can be absolved by the proper weld. Using the right pattern combined with the speed of the wire can greatly affects penetration can determine whether a weld is weak or strong.

Stripped Down And Built Back Up

Our once-Ford-now-Dodge Dana 60 was quickly carted off to Currie's chemical cleaning cabinet where a caustic steam bath stripped the housing bare of any grease, gear oil, grit, and debris before fabrication could begin. Once cleaned, the housing was chucked up on a jig and measured and marked for narrowing.

Although we're keeping the housing within stock Chrysler measurements (a 44-inch center of pad-to-pad width and 54-inches from one backing plate flange to the other), the axle tubes needed to be shortened for the new bearing end caps to be welded on. A benefit of using a full-sized truck housing are the thicker tubes (up to 1/2-inch), which allowed us more material to chamfer down to build a better weld bead.

Ready to put some heat to the housing, a pair of machined aluminum discs were bolted into carrier bearing races as a six-foot rod of round aluminum stock was slid into place. A third disc was fit into the end of the new end cap and slid onto the bar to hold the cap in place, ensuring that the tube end stayed properly aligned while being welded.

Squared and true, a sequence of slow, high heat beads bonded the end caps to the axle tubes, overlapping one over the other. Wire-wheeled clean, the housing was measured and squared up again to receive the factory-style leaf spring perches supplied by Competition Engineering.

With all of the welding completed, the housing was sent to a material blaster, where the housing is stripped by media that strips and welding flash, paint, and solvents from the metal, leaving completely virgin, bare steel.

Once Currie completed all of the fabrication work, the housing was sent back to the material cleaning department for an aggressive media treatment. This stripped the housing down to bare metal without the use of caustic chemicals while knocking off any welding flash, removing any embedded contaminants, or oil residue, making it now ready for assembly.

Building A Budget Dana 60 By The Numbers:

- Dana 60 Chrysler Rear Housing (44″ center of pad-to-pad width, 54″ between backing plate flanges width)

- Currie Forged Alloy Extreme 35-spline Axles, offset pair 28-7/16″ and 27-1/16″ (# CE-1014)

- Currie Sealed Large Axle Bearings With O-Rings (# CE-8000S)

- Motive Gear 4.56 ring and pinion (# D60-456)

- Detroit Locker 35-spline (# DET225S-29)

- Competition Engineering Rear Axle Spring Perches, 2-1/2″ wide (# 85090)

- Yukon Gear Billet Yoke (# YY D60-1350-B)

The Filling Is Always The Best Part

Currie's forged alloy axle shafts are made to order, from milling the 35-splines, to drilling and tapping the blank axle flanges for a set of large 5/8-inch lug bolts.

In planning for Killer Kong's powertrain, we're looking at building a big-cube HEMI pressing out somewhere between 650 and 700 horsepower, with a reverse manually-shifted 727 Torqueflite automatic snapping quick shifts between 6,000-to-6,5000rpm on the rare occasion that its on the track and not on the street.

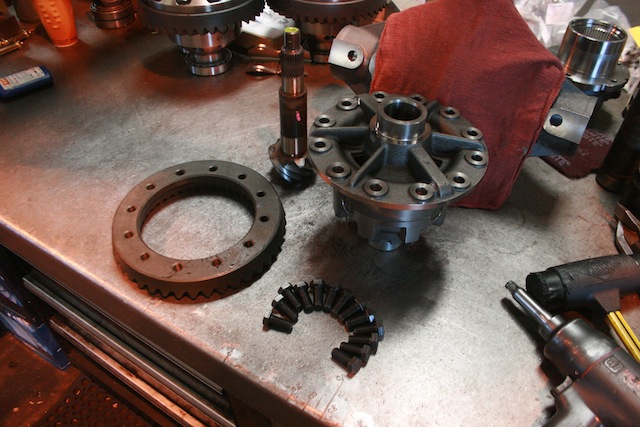

That being said, we knew we had to build this Dana with some pretty stout stuff. We first contacted EATON for a Detroit Locker differential. Thankfully, things have changed since the early days, and today's Lockers are nowhere as clanky and noisy as they were twenty years ago.

Plus, since the Charger is far heavier than so many stripped-down pony cars running similar setups, our Locker won't be loosely indexing through gears around corners.

Ultimately, the Detroit Locker was the logical choice considering the power we were looking to make and needed to put to the pavement while not sacrificing streetability as we would with say, a spool.

Next, we made a call to Motive Gear, who rushed out a 4.56 ratio ring and pinion set. Normally, such a low gear ratio would make highway driving arduous, but as the Charger is close to 3,800-pounds and running a 30-inch tall rear tire, the aggressive gearing made the most sense.

Of course, Currie supplied all the new bearing races, seals, shins, and bearings, as well as a pair of 35-spline forged alloy axle shafts. After milling the axle shaft with the 35-count splines, the blank axle flanges were drilled and tapped for the larger 5/8-inch lug bolts (at factory Chrysler 5 x 4.5-inch pattern).

Weapons of war: EATON's Detroit Locker is known in performance circles as being "grenade-proof," and we believe it. That, combined a burnout-happy set of 4.56 gears from Motive Gear, our Dana 60 is quickly adding up to be one mean machine.

Before final assembly, a bit more work needed to happen. Our Currie specialist, Abraham, first notched the carrier bearing perches. This allows gear oil to flow freer through the axle tubes and the housing, reducing fluid and bearing heat. Next, to get a baseline for the new gears and Detroit Locker, Abraham loosely assembled the pinion and carrier with a variety of different shims to find the perfect alignment. Tolerances need to be precise with applications like these, or the extreme forces within the housing can cause accelerated wear and possible mechanical failure.

It's the little tricks picked up over the years that make for a well-oiled rearend (pun intended). By scoring the bearing seals, gear oil is able to pass freely from the axle tubes to the carrier, while passing continually through the carrier bearings. Cost? Nada.

Using a dial indicator to check the backlash and some yellow marking dye to check the engagement of the ring and pinion gears, Abraham was able to adjust the final alignment by shimming the carrier bearings and pinion gear for proper engagement.

To install the pinion gear, first a new bearing race needed to be pressed into the housing. Next, the pinion gear was assembled on a vertical press with a cone bearing and a collection of measured shims. From the front of the housing, a second series of shims, bearing, slinger bearing, crush sleeve and an oil seal were pressed in, tightened down with a new Yukon Gear yoke and nut, with the pinion preload adjusted.

With a dollop of red thread locker, the 4.56 ring gear was bolted to the carrier, with each bolt torqued down to 110-pounds. Assembled with the right amount of shims, the carrier bearings were pressed on. Covered in a bead of red Loc-Tite, the races covered the carrier bearings as the whole Locker was lowered into the housing. Finally, the caps were torqued down to 80 lb-ft.

The key to building a stout, long-lasting rear is in the preparation. Checking, double-checking and rechecking tolerances and play is central to putting a rearend together that will last.

With our center section dialed-in and fully assembled, the 35-spline axles were assembled – much like the pinion gear – on the vertical press, sandwiching the sealed axle bearings and backing plates. Having been pre-drilled and tapped for the large lug bolts, they were threaded in from the backside of the axle flange with another trusty dollop of red thread locker.

Puttin' On The Brakes (Literally)

All of Currie's heavy duty 11-inch drum brakes come new and ready for service, either on a hot rod, a street car or a drag racer. The drums come blank and are specifically drilled to match your lug pattern and size.

But before the axles could be slid into the housing and indexed into the Detroit Locker, we attached our new 11-inch drum brakes to the end caps. The choice to run drums over say, a new set of aftermarket 4-piston calipers was two fold.

Currie's Brian Shephard made a convincing argument, "Well, in [Killer Kong's] application, a foot-brake drag racing application, you just have to think about the sheer surface area of the pad material of the drum compared to the disc brake. When you are trying to hold back a 4,000 lb., 600-plus horsepower car with the brakes – you need surface area!"

That surface area was dramatically increased from our Charger's original factory specs; stepping up from 9-inch drums to heavy duty 11-inch drums was a no-brainer. Thankfully, 11-inch drums are still in abundance in most automotive salvage yards, you just need to look out for Chrysler-made station wagons, light duty trucks, and vans from the late 1960's all the way through the mid-1980's.

Secondly, was the most obvious, cost. While rear disc brakes have become more common, they are still – on average – $600, while a solid set of HD drums will set you back close to half of that. And since we're putting in Currie's brand new 11-inchers, we don't need to change any of our factory brake cables. Oh, the simplicity!

All of Currie's drums come blank and are specifically drilled to match the lug pattern and size of the axle package. Since we went with the larger 5/8-inch diameter lugs, Currie bored out to match our Dodge's 5 x 4.5 pattern.

From drum to drum, filled with some of the stoutest running gear available for a street-driven Mopar, this Dana 60 came in at nearly half the cost of purchasing a new one.

From junkyard scrap to a bad ass Dana 60 worthy of 1,000-horsepower in a day, we buttoned up this monster axle housing for half the cost of purchasing a brand-new 9.75 rear from an aftermarket company. While nothing nearly as exotic as some of the stuff they're capable of building, Currie Enterprises made short work out of this budget Dana 60. Now, we just need to bolt it up into Killer Kong and get her rollin'!

Source: https://www.streetmusclemag.com/tech-stories/drivetrain/currie-builds-killer-kong-the-ultimate-budget-dana-60/

0 Response to "Installed a Real Locker Now My Rear Tires Show a Funny Wear Pattern"

Postar um comentário